ABOUT US

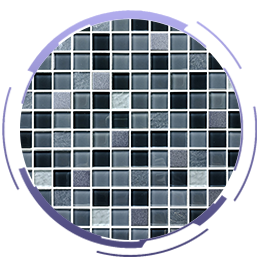

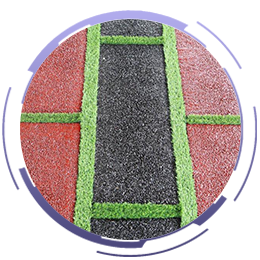

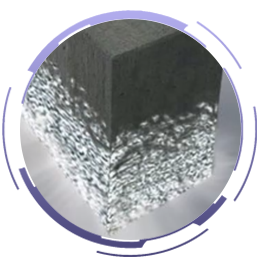

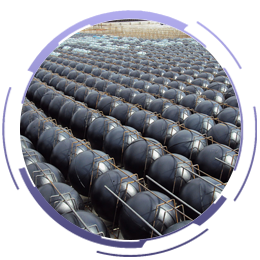

ICM Technology manufactures and provides cutting-edge construction materials and nanomaterial products. Featuring unsurpassed energy efficiency, our product line has been developed to meet all requirements of the modern-day construction. Our high quality yet cost-effective concrete and nanomaterial products use a unique patented technology that helps reduce construction time and keeps costs low. ICM Tech products yield high-quality constructions with unique energy saving properties.

Vision

To improve infrastructure through meaningful innovations and continuous emphasis on meeting the needs of our clients without losing sight of value, environment, and society. To foster an internal environment of innovation, collaboration, and trust.

Mission

Our primary mission is to advance the frontiers of construction experience and enrich as well as elevate the citizens of Thailand, ASEAN, and the World, to conduct ourselves with integrity and live up to our company values and to contribute towards the growth of an increasingly discerning market and industry while and achieving customer satisfaction not only for outstanding workmanship, but also for quality, concept functionality, and style.

Values

We believe that putting our values into practice creates long-term benefits

for the shareholders, customers, employees, suppliers, and the communities

we serve. We want our decisions and actions to demonstrate these values.

We take responsibility for QUALITY

We take

responsibilities for QUALITY

We deliver

CUSTOMER satisfaction

We provide LEADERSHIP

as a company and as individuals

We act with

INTEGRITY in all we do

We regard our SUPPLIERS

as essential team members

Production

We believe that putting our values into practice creates long-term benefits

for the shareholders, customers, employees, suppliers, and the communities

we serve. We want our decisions and actions to demonstrate these values.